ENGINEERING CAPABILITIES

Providing a full range of design, development, testing and validation services.

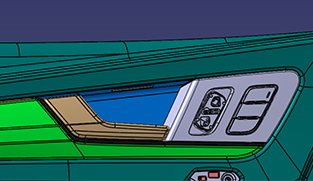

Product design

- “Black Box” design capable

- Optimization of customer designs

- Siemens NX, CATIA V5, SolidWorks

- Multi-disciplinary design reviews

- TeamCenter, KVS & other automotive OEM customer portals

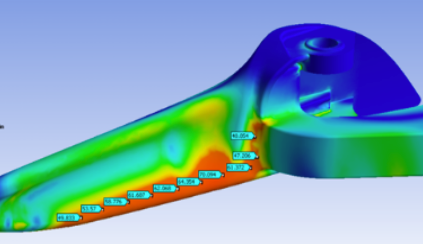

analysis

- Autodesk Moldflow Insight

- Molding process optimization (fill time, pressure, temperature balanced flow)

- ANSYS Non Linear FEA software

ENGINEERING & TECHNOLOGY

- Design Responsible & Build to Print

- Program Management

- Advanced Engineering

- Research and Development

TESTING/VALIDATION

- Design Responsible & Build to Print

- Program Management

- Advanced Engineering

- Research and Development

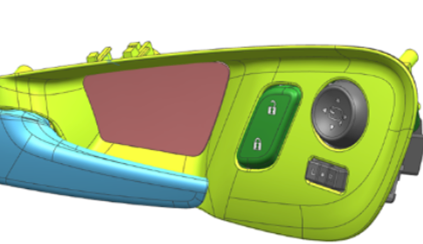

prototypes

- Rapid prototyping

- Fixture and production conceptualization

- Dedicated prototype assembly area

- In house 3D printing

Program management

- Dedicated Program Managers

- Weekly status reports

- On-site plant support

- APQP / VDA guiding principles

- Extensive business transfer experience

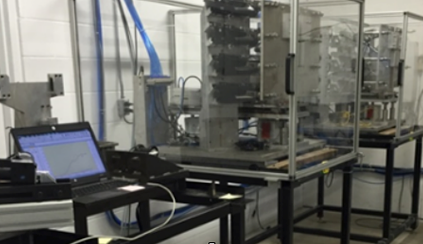

Tooling

- Fully equipped in-house tool room for maintenance and modifications

- In-house design and fabrication of test fixtures, EOAT and assembly automation

- In House Capabilities:

- CNC

- EDM

- Welding

- Spotting

- Polishing