MANUFACTURING CAPABILITIES

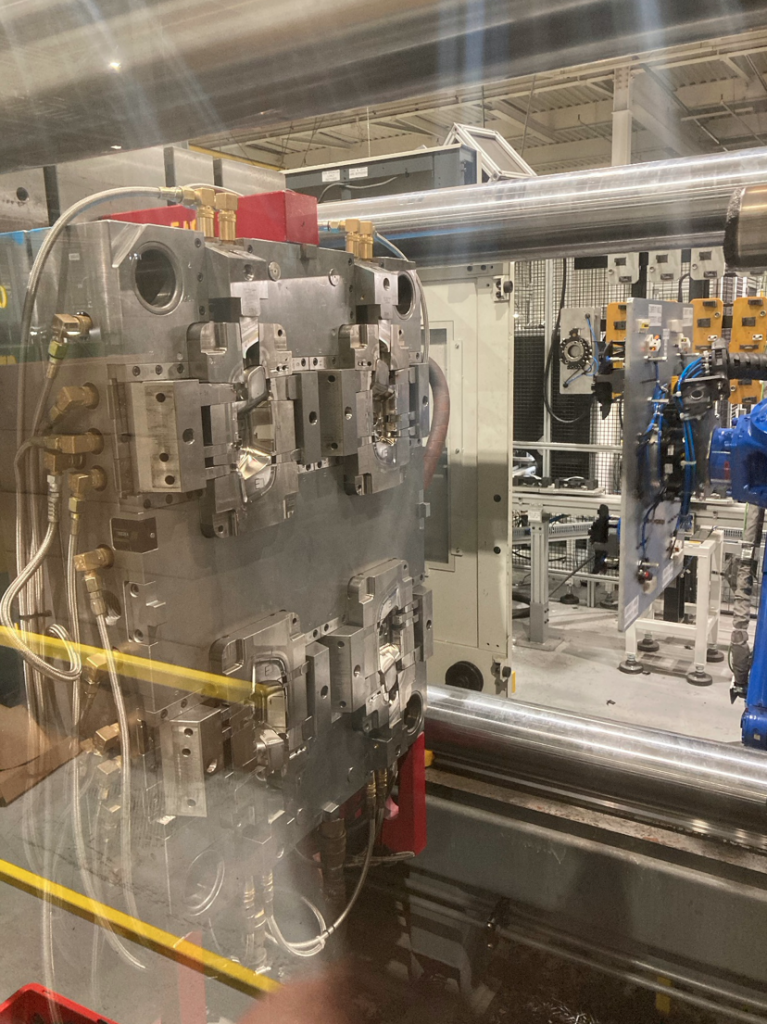

PLASTIC INJECTION MOLDING

- Machines ranging from 60 to 1,450 tons

- 3 axis & 6 axis robots for demolding

- Single shot, multi-shot and gas assist and over-molding

- Metallic plastic molding

- Robotic loading / unloading / vision systems

- Cushion monitoring for short shot detection

- Structural and Class ‘A’ components

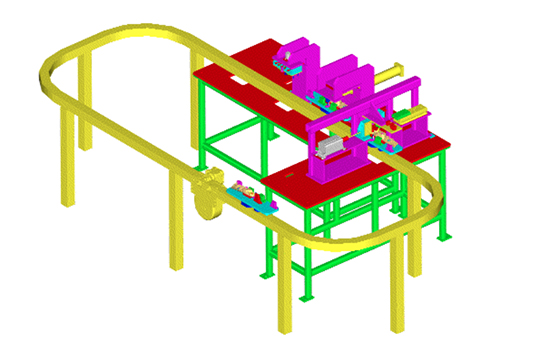

ASSEMBLY

- Balanced combination of automated and manual assembly

- Single piece flow from molding through assembly

- In-line Poka-Yoke quality checks

- Heat staking

- Vibration welding

- Hot stamping and post mold foil printing

- Screw insertion

- Assembly cells tied to moulding machines

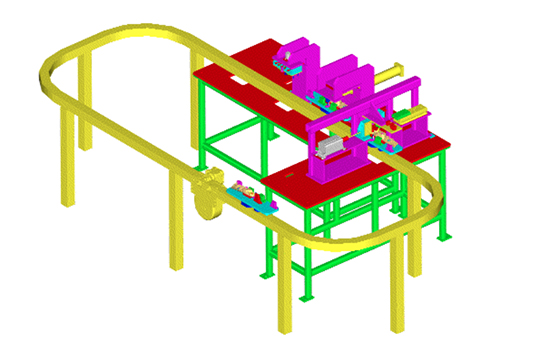

ASSEMBLY

- Balanced combination of automated and manual assembly

- Single piece flow from molding through assembly

- In-line Poka-Yoke quality checks

- Heat staking

- Vibration welding

- Hot stamping and post mold foil printing

- Screw insertion

- Assembly cells tied to moulding machines

PAINTING / CHROME PLATING

- Chrome plating: plastic & zinc / interior & exterior

- Painting: e-coat, powder coat, soft touch, plastic, exterior

- OEM approved domestic and LLC sources

- ISO/9001 subcontractors

- Molder / Plater status